Design Simulation

Casting Simulation Software Suite PoligonSoft (CSS) “PoligonSoft” is the professional tool for the creation and optimization of the foundry technology. “PoligonSoft” works on the basis of finite elements method and performs the analysis of fillining, crystallization and stresses for the most part of the casting technologies and any alloys.

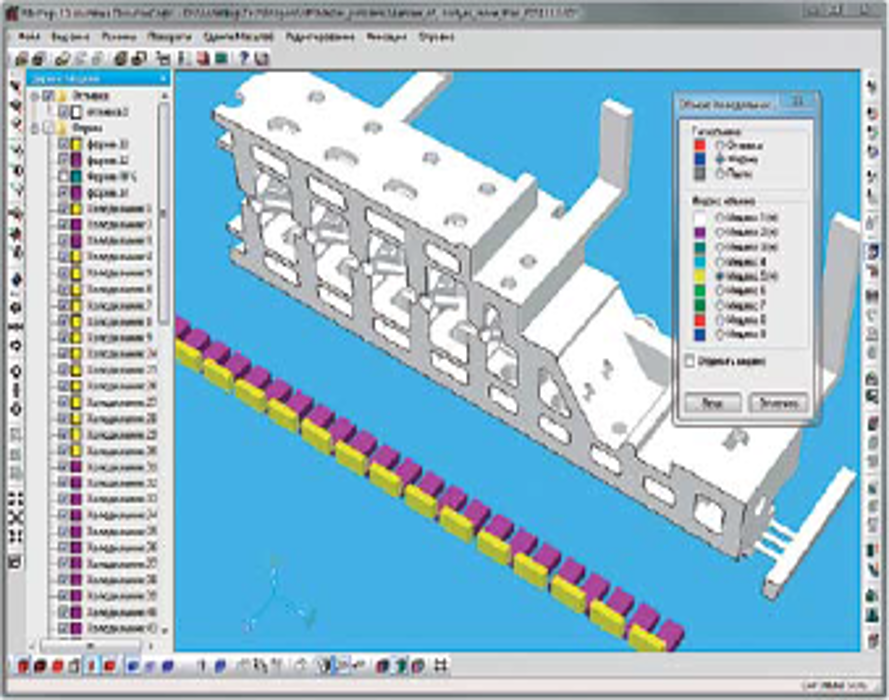

Work with the geometry of any complexity

Thanks to the finite element approach CSS “PoligonSoft” works correctly with the geometrical model of casting block of any complexity consisting of a multitude of bodies of arbitrary shape. The cooling plates, sand cores, support fillers, mold boxes, heat insulating materials and elements of melting equipment affect the quality of the foundry to some extent and this influence can be taken into account in the calculation.

The module “Master-3D” allows to download and to use the meshes of the following formats: Altair HyperMesh, ANSYS, ProCAST, Nastran, CATIA V5, NEU, GiD, ISPA. The user only needs to download the file with mesh model of casting block and “Master-3D” will independently determine what bodies are the foundry and what are the elements of the mold and will assign the boarders of the bodies interface

PoligonSoft Features

Filling of the mold

“Euler-3D” module allows to calculate the filling of the mold with the melt with constant or variable speed through one or several sprues. With its help you to analyze:

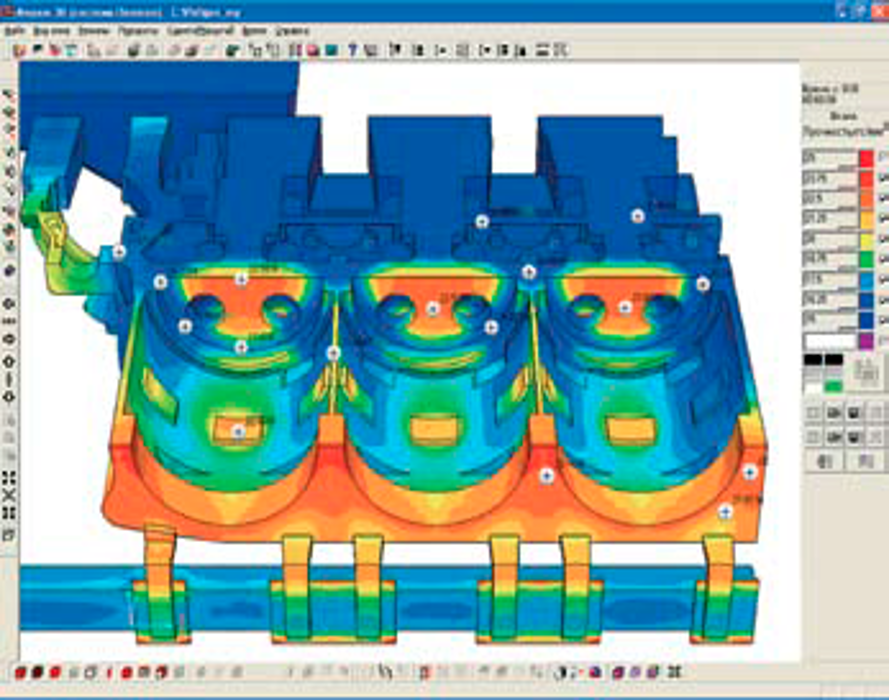

Cooling of the foundry and the mold

“Fourier-3D” module performs the calculation of the temperature and phase fields taking into account the heat generation during crystallization, solves the filtration task including the simulation of the pressure fields. The module allows to calculate:

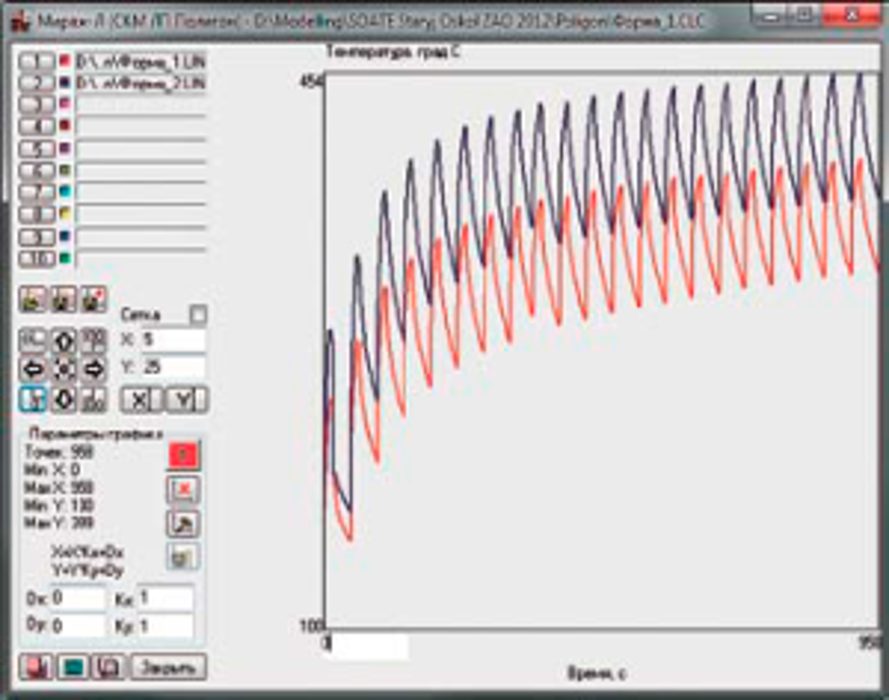

Cyclic processes

In some casting methods (press molding, for example) it is important to determine the moment when the mold opens out the temperature regime that will determine the quality of the products. “Fourier-3D” allows to perform the cyclic calculations and to consider the mold heating during previous cycles, cooling of the mold at the moment of mold joint, installation of the cores.

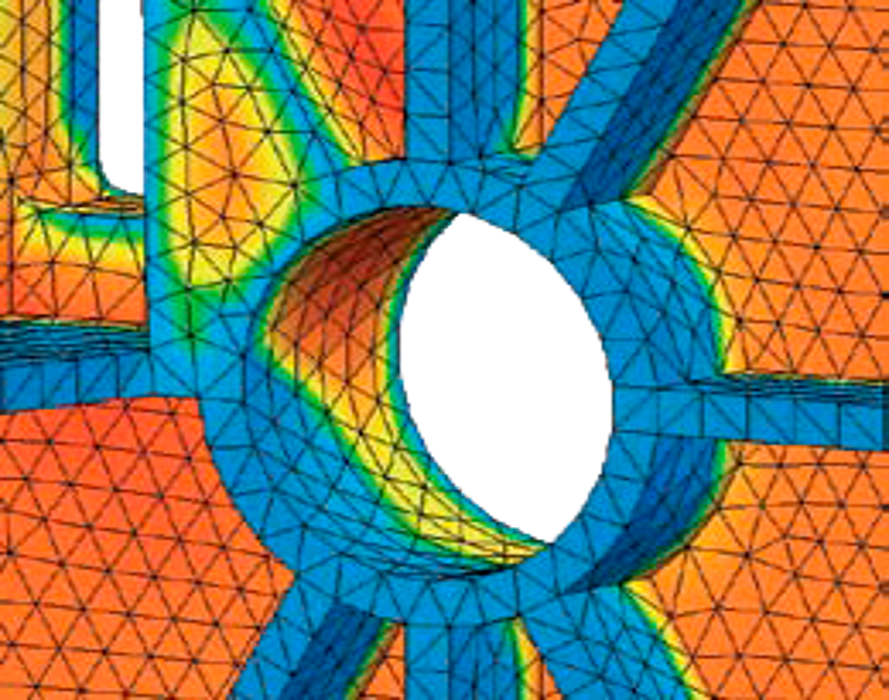

Warpage and craсkes

“Hooke-3D” module is designed to calculate the temperature stresses and strains that occur in the foundry and the mold during cooling stage. The calculation is performed on the basis of the theory of small elastoplastic strains created by A. Ilyushin and Newton method. The module allows to calculate:

CSS «PoligonSoft” for bulky foundry

Due to the use of the finite element method, the “PolygonSoft” system is successfully used for modeling very large and at the same time comparatively thin-walled castings.

In combination with the ability to use symmetry and multithreaded computation, the modeling process takes quite an acceptable time. At the same time, the computing resources used (primarily the amount of RAM) do not go beyond the boundaries of ordinary office PCs.

Additional possiblities

CSS “PoligonSoft” has big possibilities of criteria analysis of received results. It is possible to calculate and to analyze such properties as structure, hardness, metal penetration, washing, cooling rate, etc with the help of the module «Criteria-3D”. The module contains a wide range of built-in functions that allow the user to create their own analysis criteria that correspond to a particular production: degrees, logarithms trigonometric, gradients, rate of change, search for minimum and maximum values, and many others.